Understanding Diecast Quality Control

Diecast quality control is the process of ensuring that diecast products meet specified standards for quality, reliability, and performance. It encompasses a range of activities, from the selection of raw materials to the final inspection of finished products. The goal of diecast quality control is to identify and eliminate defects, minimize waste, and ensure customer satisfaction. Effective quality control not only improves the final product but also streamlines the manufacturing process, reducing costs and enhancing efficiency. This proactive approach is critical in the competitive diecasting industry, where precision and consistency are paramount.

Importance of Diecast Quality Control

The importance of diecast quality control cannot be overstated. High-quality diecast products are essential for the safety and functionality of various applications, from automotive components to consumer electronics. Without rigorous quality control measures, defects can lead to product failures, safety hazards, and reputational damage for manufacturers. By implementing comprehensive quality control processes, businesses can maintain a competitive edge, reduce costs associated with rework and returns, and build customer trust. Furthermore, adhering to stringent quality standards is often a legal requirement, particularly in industries where product safety is critical. Investing in robust quality control is thus a strategic imperative for any diecasting operation.

Benefits of Effective Diecast Quality Control

The benefits of effective diecast quality control are numerous and far-reaching. Firstly, it leads to a reduction in product defects, which translates into fewer warranty claims and customer complaints. Secondly, it improves manufacturing efficiency by minimizing downtime and waste. Efficient processes mean less time spent correcting errors and re-casting flawed parts, reducing the overall cost of production. Thirdly, robust quality control contributes to enhanced product reliability and durability, resulting in increased customer satisfaction. Lastly, adherence to strict quality standards can open doors to new markets and business opportunities. By prioritizing quality control, diecasting companies can achieve sustainable growth and maintain a strong competitive position.

Tip 1 Inspect Raw Materials

The foundation of high-quality diecast products begins with the careful inspection of raw materials. This involves verifying that the materials meet the required specifications and are free from defects. Proper material selection is critical, with the chosen alloys having the right properties for the intended application. Regular audits of suppliers, material certifications, and the use of reliable testing methods are essential components of this process. Failure to inspect raw materials can lead to a cascade of issues during the manufacturing process, ultimately resulting in flawed products. Therefore, the initial inspection stage must be thorough and meticulous, as it forms the cornerstone of the overall quality control strategy.

Material Inspection Procedures

Material inspection procedures should be clearly defined and consistently followed. They usually involve visual inspections, chemical composition analysis, and mechanical testing. Visual inspections are used to detect surface defects, such as cracks, porosity, and inclusions. Chemical analysis confirms that the alloy meets the required elemental composition, while mechanical testing, such as tensile strength and hardness tests, ensures that the material possesses the necessary physical properties. These procedures must be documented, and records should be maintained for traceability. Periodic reviews of inspection processes, combined with training for inspectors, are crucial to maintain high standards. Using calibrated equipment and following industry standards, such as those from ASTM or ISO, ensures the reliability and validity of inspection results.

Identifying Material Defects

Identifying material defects early in the process is essential to prevent downstream problems. Common defects include porosity, inclusions, segregation, and cracks. Porosity can be caused by gas entrapment during the melting or casting process. Inclusions, such as oxides or foreign particles, can weaken the material. Segregation occurs when the alloy components are not evenly distributed. Cracks can result from thermal stress or mechanical damage. Inspectors must be trained to recognize these defects through visual examination, and advanced techniques, like X-ray inspection or ultrasonic testing, may be used to identify internal flaws. Establishing acceptance criteria and rejection standards for different types of defects is also vital to maintaining consistent product quality.

Tip 2 Careful Die Design and Maintenance

The die design is another essential factor in the overall quality of diecast parts. Poorly designed dies can lead to various defects, including dimensional inaccuracies, surface imperfections, and premature die failure. Good die design considers factors such as the type of alloy, part complexity, and production volume. The die must be designed to facilitate proper metal flow, efficient cooling, and easy part ejection. In addition to design, careful die maintenance is crucial to prolonging die life and ensuring consistent part quality. This involves regular cleaning, lubrication, and inspections to identify and address any wear or damage.

Die Design Considerations

Several design considerations are critical for producing high-quality dies. These include optimizing gate and runner systems to ensure even metal flow, designing cooling channels to prevent distortion and minimize cycle times, and incorporating features to facilitate part ejection. The die material itself must be selected to withstand the high temperatures and pressures involved in the diecasting process, and the die should be designed to withstand thermal and mechanical stresses. Simulation software can be used to model the diecasting process, optimizing the die design and minimizing potential defects. Consideration should also be given to the part’s draft angles, parting lines, and overall complexity, as these factors influence the die’s manufacturability and performance.

Die Maintenance Schedule

A well-defined die maintenance schedule is essential for preventing defects and extending die life. This includes regular cleaning to remove any build-up of metal or debris, lubrication to reduce friction and wear, and inspections to identify any damage or wear. The frequency of maintenance depends on factors such as production volume, the complexity of the part, and the type of alloy being cast. A comprehensive maintenance program also involves routine inspections of the die’s critical components, such as the core pins, ejector pins, and slides. Any damage must be addressed immediately. Records should be kept of all maintenance activities, ensuring traceability and enabling continuous improvement in die performance.

Tip 3 Precise Casting Parameters

Controlling casting parameters is critical for producing diecast parts of consistent quality. These parameters include temperature control, injection pressure, injection speed, and cooling time. Precise control of these variables ensures that the molten metal fills the die cavity completely and solidifies uniformly. Any deviation from the optimal parameters can result in defects such as porosity, shrinkage, and dimensional inaccuracies. Therefore, diecasting operations must invest in advanced equipment and technologies to monitor and control these parameters, as well as develop a system to promptly address any inconsistencies.

Temperature Control

Temperature control is one of the most critical aspects of the diecasting process. The temperature of the molten metal must be precisely controlled to ensure proper filling of the die cavity and to prevent defects such as porosity and cold shuts. Overheating can lead to oxidation and other material degradation. Insufficient temperature will result in poor metal flow, leading to incomplete filling and potential defects. Consistent temperature control also applies to the die itself. Proper cooling of the die is essential to solidify the metal quickly and to minimize distortion. Temperature sensors and control systems are crucial to maintaining these parameters within the optimal range.

Injection Pressure and Speed

Injection pressure and speed are other vital parameters that directly affect the quality of the casting. The injection pressure must be high enough to fill the die cavity completely, while the injection speed must be optimized to minimize turbulence and air entrapment. Excessive injection pressure can cause flash, a thin layer of excess material at the parting lines, while insufficient pressure can lead to incomplete filling. The injection speed is usually adjusted depending on the part’s complexity and wall thickness. Modern diecasting machines are equipped with sophisticated control systems that enable precise adjustment and monitoring of these parameters, contributing to consistent and high-quality production.

Tip 4 Post-Casting Inspection

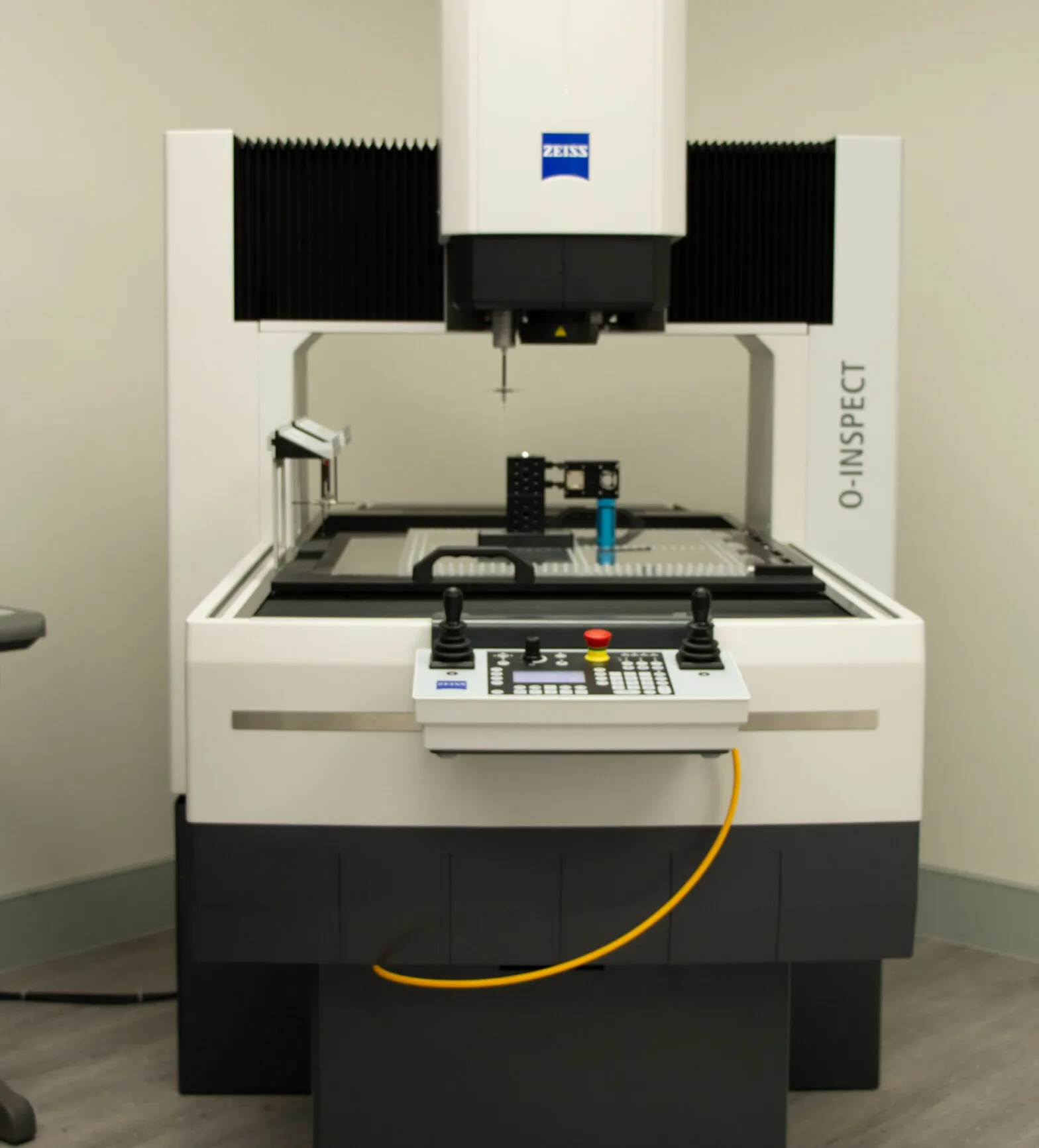

Post-casting inspection is a crucial stage of the quality control process, involving the visual examination and dimensional checks of the cast parts. The goal is to identify and eliminate defects before the parts move to the finishing stage or are shipped to customers. This involves a combination of manual inspection and automated inspection techniques, such as optical scanners and coordinate measuring machines (CMMs). Consistent and well-defined inspection procedures are essential. Any defects found during the inspection should be documented, and corrective actions should be taken to prevent them from recurring in future production runs.

Visual Inspection Techniques

Visual inspection is a fundamental part of the post-casting inspection process. This involves a thorough examination of the casting’s surface to identify any defects, such as cracks, porosity, flash, and surface imperfections. Inspectors typically use a combination of visual aids, such as magnifying glasses and bright lighting, to enhance the detection of defects. The inspection process must be standardized, with clear acceptance criteria and rejection standards. It is important to establish training programs for inspectors. Regular audits should be performed to ensure that the inspection procedures are being followed correctly and consistently. It’s often useful to create a detailed checklist that inspectors can use for each part.

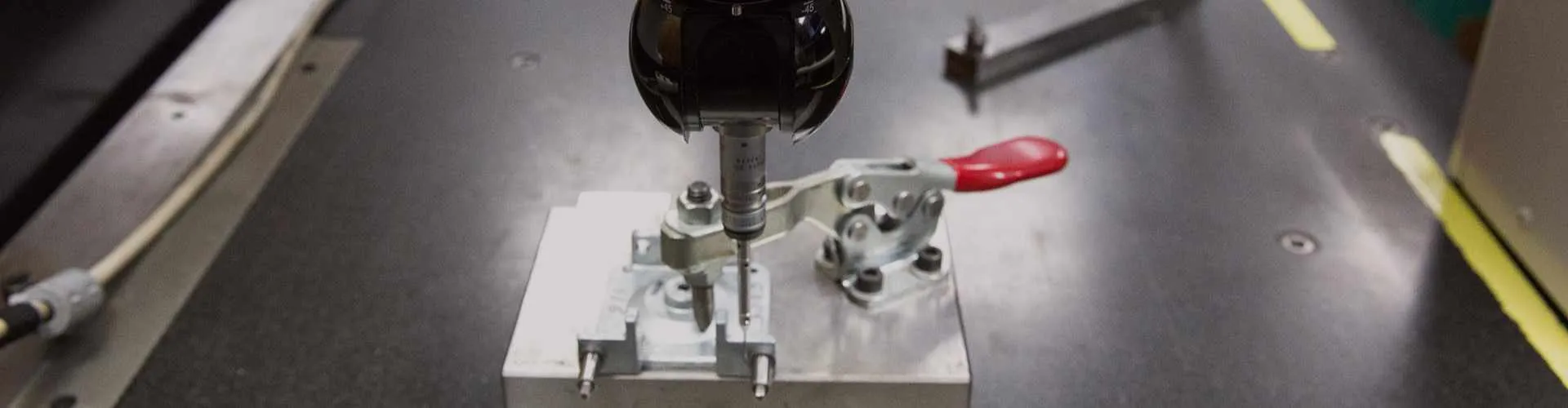

Dimensional Checks

Dimensional checks are essential for verifying that the cast parts meet the specified dimensions. Coordinate measuring machines (CMMs) are widely used for this purpose. CMMs measure the part’s dimensions with high precision, comparing them to the design specifications. The use of CMMs allows manufacturers to identify any deviations from the design and take corrective action. In addition to CMMs, other dimensional measurement tools, such as calipers, micrometers, and gauges, may be used for specific measurements. A comprehensive dimensional check should include measurements of critical features, such as holes, threads, and surfaces. This will guarantee that the parts are within the required tolerances and will function correctly.

Tip 5 Finishing Process Control

The finishing process involves a series of operations to improve the appearance and functionality of the diecast parts. This may include trimming, deburring, surface treatment, and coating or painting. Each of these steps must be carefully controlled to ensure that the parts meet the required quality standards. The selection of the finishing processes depends on the part’s application and the desired cosmetic and performance characteristics. Maintaining consistent quality in finishing processes also requires skilled personnel, proper equipment, and detailed standard operating procedures (SOPs).

Surface Treatment Techniques

Surface treatments are applied to diecast parts for a variety of purposes, including corrosion resistance, wear resistance, and improved aesthetics. Common surface treatment techniques include anodizing, plating, and passivation. Anodizing is used to create a protective oxide layer on aluminum parts, while plating involves applying a layer of another metal to the surface. Passivation creates a protective layer, improving corrosion resistance. The specific surface treatment technique will depend on the alloy being used, the environment in which the part will be used, and the desired performance characteristics. Rigorous control over the surface treatment process is critical to ensure the quality and durability of the finished product.

Coating and Painting Quality

Coating and painting are often used to enhance the appearance of diecast parts and to provide additional protection. The quality of the coating or painting is determined by factors such as adhesion, uniformity, color accuracy, and durability. Proper surface preparation, including cleaning and priming, is essential for achieving good coating adhesion. The coating or painting process must be carefully controlled to ensure a uniform finish and to prevent defects such as runs, sags, and bubbles. Quality control measures during the coating process include visual inspection, thickness measurements, and adhesion testing. The use of high-quality coatings and paints also contributes to the overall quality and durability of the finished parts.

Tip 6 Testing and Quality Assurance

Testing and quality assurance are integral to the diecast quality control process. These measures involve using a variety of tests to assess the mechanical properties, dimensional accuracy, and overall performance of the cast parts. Both destructive and non-destructive testing methods are used to ensure product quality. Adhering to established testing protocols and industry standards is also essential to guarantee the reliability and validity of the test results. These test results provide valuable data for continuous improvement efforts.

Destructive Testing

Destructive testing involves testing parts to failure to evaluate their mechanical properties. Common destructive tests include tensile tests, which measure the part’s strength and ductility; hardness tests, which assess the material’s resistance to indentation; and impact tests, which measure the material’s ability to absorb energy. These tests provide valuable data on the material’s mechanical behavior. The results of destructive testing can be used to verify that the material meets the specified requirements. Additionally, such testing aids in identifying potential weaknesses. This allows manufacturers to make informed decisions regarding material selection, die design, and manufacturing processes. Destructive testing typically follows industry standards to ensure the accuracy and comparability of the results.

Non-Destructive Testing

Non-destructive testing (NDT) methods allow for the evaluation of cast parts without damaging them. Common NDT techniques include X-ray inspection, ultrasonic testing, and dye penetrant testing. X-ray inspection is used to detect internal defects, such as porosity and inclusions. Ultrasonic testing uses sound waves to detect internal flaws and to measure the material’s thickness. Dye penetrant testing reveals surface cracks and other surface imperfections. NDT methods provide a rapid and reliable means of assessing the quality of diecast parts. They are particularly useful for detecting hidden defects that may not be visible during visual inspection. Proper training and certification of the NDT personnel are essential to ensure the accuracy and reliability of the test results.

Tip 7 Documentation and Continuous Improvement

Effective documentation and a commitment to continuous improvement are crucial components of a successful diecast quality control system. Maintaining accurate records of all quality control activities is essential. This includes inspection results, testing data, and any corrective actions taken. Data collected through these processes should be regularly analyzed to identify trends, to detect recurring problems, and to evaluate the effectiveness of quality control measures. The data forms a baseline for future improvements and ensures traceability. An organization must also cultivate a culture of continuous improvement, encouraging employees to actively participate in identifying and implementing process improvements.

Maintaining Accurate Records

Maintaining accurate records of all quality control activities is essential for traceability, for problem-solving, and for continuous improvement. These records should include inspection reports, testing data, and details of any corrective actions taken. A well-organized record-keeping system enables the manufacturer to quickly identify the root cause of any defects or quality issues. The records should be easily accessible and readily available for review. The records also are valuable for validating the quality of the parts. The data is also used for regulatory compliance and for audits. Modern quality control systems often utilize digital record-keeping to streamline this process and to enhance data management and analysis.

Implementing Corrective Actions

When defects or quality issues are identified, it’s crucial to implement corrective actions. This includes identifying the root cause of the problem and taking steps to prevent the issue from recurring. This could involve making changes to the die design, adjusting the casting parameters, or improving the finishing processes. Corrective actions should be documented and verified to ensure that they are effective. Regular audits of the quality control system should be performed to assess its effectiveness and to identify areas for improvement. A proactive approach to corrective actions, combined with a commitment to continuous improvement, is essential for maintaining the high-quality diecast parts.

Conclusion

Implementing robust diecast quality control processes is not just a best practice, but a necessity for manufacturers in the competitive market. From rigorous raw material inspections to the precise control of casting parameters and the meticulous application of finishing processes, each step plays a crucial role in delivering high-quality, reliable diecast products. By embracing the seven tips outlined, including careful die design, a focus on post-casting inspection, and the application of testing and quality assurance, manufacturers can minimize defects, reduce costs, and enhance customer satisfaction. Furthermore, the establishment of detailed documentation systems, coupled with a commitment to continuous improvement, ensures sustained quality and drives innovation in the diecasting process.