In the world of manufacturing, particularly when it comes to intricate and detailed products like diecast models, ensuring top-tier quality is paramount. Diecast quality services are not merely an added expense; they are a crucial investment in the longevity, functionality, and overall value of your products. From the initial design phase to the final product, every step demands meticulous attention to detail and adherence to rigorous quality standards. This guide delves into the critical aspects of diecast quality services and provides insights on how to ensure perfection in your diecast manufacturing processes. By understanding these services, manufacturers can significantly reduce defects, boost customer satisfaction, and achieve a competitive edge in the market. Let’s explore how to ensure excellence at every stage of the diecast production journey.

Understanding Diecast Quality Services

Diecast quality services encompass a range of activities designed to assess and ensure the quality of diecast products. These services are integral to the manufacturing process, helping to identify and rectify potential issues before they impact the final product or, more importantly, the end-user. The ultimate goal is to consistently produce high-quality diecast parts that meet all required specifications, including dimensional accuracy, surface finish, and overall performance. These services help guarantee that the final product not only looks aesthetically pleasing but also functions reliably and meets the expected standards of durability and performance.

What are Diecast Quality Services

Diecast quality services consist of various inspection, testing, and analysis processes performed throughout the diecast manufacturing cycle. They include, but are not limited to, material analysis, dimensional checks, surface finish evaluations, and functional testing. The comprehensive approach helps manufacturers detect and address defects early in production, thereby saving time, resources, and preventing costly rework. By integrating these services, businesses can achieve higher efficiency and meet the specific needs of their customers.

The Importance of Quality in Diecast Production

Quality is not an option; it is a necessity in diecast production. The precision and detail required in diecast manufacturing, especially in industries like automotive, aerospace, and consumer electronics, make rigorous quality control essential. High-quality diecast products enhance the product’s reliability, durability, and overall performance. Moreover, it significantly impacts customer satisfaction and the brand’s reputation. Investing in these services results in fewer returns, increased customer trust, and a stronger competitive position in the market. Implementing robust quality control measures is vital for success.

Key Aspects of Diecast Quality Services

Effective diecast quality services involve several critical processes that ensure product excellence. Each service plays a vital role in identifying potential issues and ensuring that the final product meets the required specifications. Proper implementation of these aspects is critical for achieving optimal results in the diecast manufacturing process, reducing defects, and increasing the overall value of the products.

Material Inspection and Testing

Before the diecasting process begins, material inspection and testing are essential. This involves verifying the chemical composition, mechanical properties, and overall quality of the raw materials, such as aluminum, zinc, or magnesium alloys. The process ensures that the materials meet the required standards and do not contain impurities or defects that could compromise the final product’s integrity. Techniques include spectroscopic analysis, tensile testing, and hardness testing to confirm that the materials possess the desired characteristics.

Surface Finish and Coating Analysis

Surface finish and coating analysis are crucial for ensuring the aesthetic appeal, corrosion resistance, and overall durability of diecast products. These services include inspecting the surface for defects like scratches, pits, and imperfections. Testing also involves analyzing the effectiveness and evenness of applied coatings, such as paint, powder coating, or plating. Methods like microscopic examination, adhesion tests, and salt spray testing are employed to evaluate the quality of the surface finish, ensuring it meets the required specifications for both appearance and protection against environmental factors. This image showcases a professional inspecting a diecast model’s surface finish.

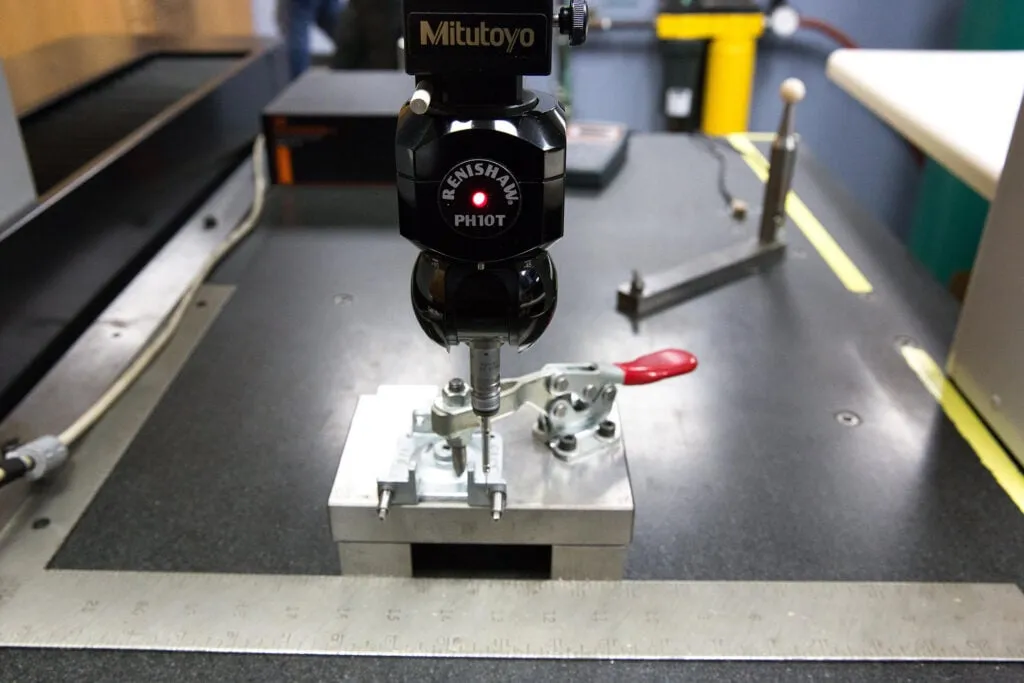

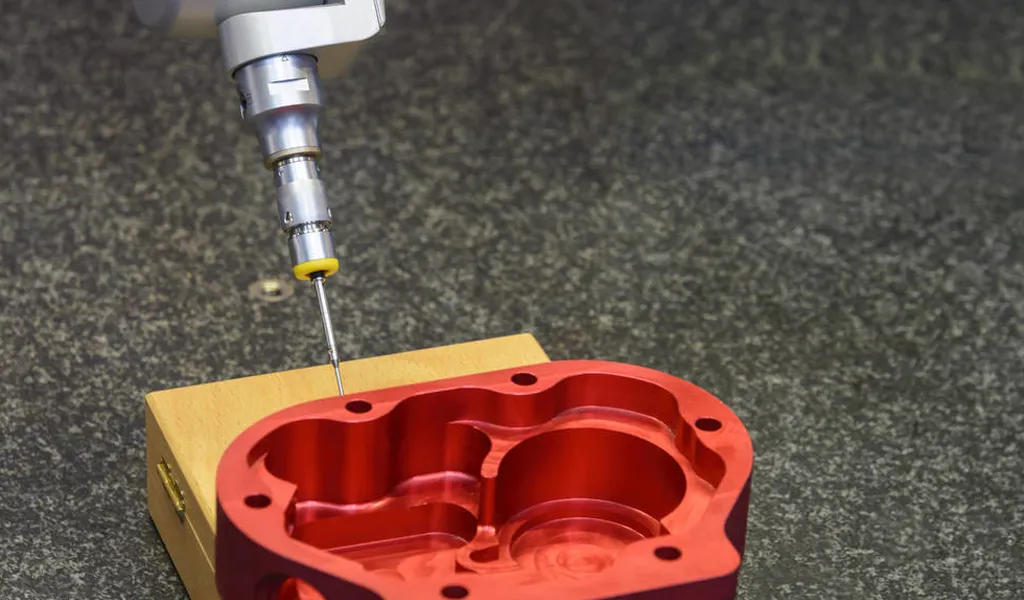

Dimensional Accuracy and Tolerance Checks

Dimensional accuracy is critical for ensuring that diecast parts fit correctly and function as intended. These services use precision measurement tools and techniques to verify the dimensions and tolerances of the manufactured parts. Techniques include Coordinate Measuring Machines (CMMs), laser scanning, and visual inspection to ensure that the parts meet the design specifications. This process is vital for maintaining product integrity and ensuring that the diecast components integrate seamlessly with other parts or systems.

Assembly and Functional Testing

Assembly and functional testing are performed to verify the performance of the diecast parts within the final product or system. This includes checking for proper fit, functionality, and overall performance under specified operating conditions. The testing involves simulating real-world scenarios to identify any issues with the assembled components, such as malfunctions or premature wear. This ensures the final product meets the functional requirements and operates reliably. For example, automotive parts undergo rigorous testing to ensure they meet all safety and performance standards, see the assembly and testing in action.

Common Quality Issues in Diecast Manufacturing

Despite the best efforts, diecast manufacturing is susceptible to various quality issues that can impact the final product’s integrity. These issues can stem from material defects, process inconsistencies, or equipment problems. Recognizing these common problems is the first step in addressing them, improving product quality, and increasing customer satisfaction.

Porosity and Voids

Porosity and voids are defects that can occur during the diecasting process, resulting in small holes or air pockets within the metal. These imperfections can weaken the part, reduce its structural integrity, and potentially lead to leaks or failures. Porosity is often caused by entrapped air or gas during the casting process, and its presence can significantly reduce the reliability and durability of the diecast components. Careful control of the diecasting parameters and processes is essential to minimize these issues, as well as inspecting the metal for any issues.

Surface Defects

Surface defects, such as cracks, blisters, and cold shuts, can detract from the appearance and performance of the diecast parts. These defects can result from various factors, including improper die design, inadequate temperature control, or contamination of the molten metal. Surface imperfections can not only affect the product’s aesthetics but also compromise its corrosion resistance and overall durability. Regular inspections and quality checks are necessary to detect and correct surface defects, which in turn, increases the value of the product.

Dimensional Inaccuracies

Dimensional inaccuracies involve deviations from the specified dimensions of the diecast parts. These can result from issues such as die wear, improper die setup, or inconsistent process parameters. Inaccurate dimensions can lead to fitment problems, assembly issues, and compromised functionality, particularly in intricate components. Precise measurement tools, such as CMMs and laser scanners, are crucial to identify and correct dimensional inaccuracies, ensuring that all parts meet the design specifications.

Best Practices for Ensuring Diecast Quality

Implementing robust practices is key to ensuring the high quality of diecast products. From carefully selecting suppliers to utilizing cutting-edge inspection techniques, each step contributes to producing flawless components. By adhering to these practices, manufacturers can mitigate risks, reduce defects, and increase overall efficiency and product reliability.

Choosing the Right Diecast Supplier

The choice of a diecast supplier is critical to the overall quality of your products. Look for suppliers with a proven track record, relevant certifications, and a demonstrated commitment to quality control. Evaluate their manufacturing processes, inspection capabilities, and their willingness to collaborate on design and quality improvements. Thoroughly review their past projects, check references, and conduct facility audits to ensure their capabilities align with your specific requirements, which will help increase product value.

Implementing Quality Control Procedures

Establishing and adhering to comprehensive quality control procedures is fundamental. These procedures should cover all stages of the manufacturing process, including material selection, die design, diecasting, finishing, and final inspection. Document all processes, establish clear quality standards, and train employees on proper procedures. Implement regular inspections, testing, and audits to monitor and maintain quality standards. This proactive approach helps ensure that any potential issues are identified and addressed promptly, minimizing defects and maximizing product reliability.

Using Advanced Inspection Techniques

Modern inspection techniques play a crucial role in accurately assessing and ensuring diecast quality. Investing in advanced technologies, such as CMMs, X-ray inspection, and optical scanners, can improve the precision and efficiency of the inspection process. These tools can detect even the smallest defects and dimensional inaccuracies, enabling early detection and correction of potential problems. These advanced techniques also provide detailed data for process improvement and can help manufacturers optimize their quality control efforts.

Benefits of Investing in Diecast Quality Services

Investing in quality services yields significant benefits that extend beyond simply meeting industry standards. It creates a ripple effect, improving various aspects of the manufacturing process, customer satisfaction, and overall business success. The following are the primary advantages of integrating diecast quality services.

Improved Product Reliability

One of the most significant benefits of diecast quality services is the improvement in product reliability. By identifying and correcting defects early in the manufacturing process, these services help ensure that the final product meets all specifications and performs as intended. This reduces the risk of product failures, increases the lifespan of the components, and enhances the overall reliability of the end product. This creates a trustworthy brand.

Reduced Production Costs

While it may seem like an added cost, investing in diecast quality services can actually lead to reduced production costs. Early detection of defects minimizes waste, rework, and the need for expensive repairs. Furthermore, improved quality control reduces the number of defective products, reducing the risk of recalls and warranty claims, which can be costly. This, in turn, allows for more efficient use of resources and materials, ultimately lowering production costs and boosting profitability. This is one of the key benefits, along with improving product reliability.

Enhanced Customer Satisfaction

High-quality diecast products lead to enhanced customer satisfaction. When customers receive products that meet their expectations in terms of performance, reliability, and appearance, they are more likely to be satisfied with their purchase. This leads to increased customer loyalty, positive reviews, and repeat business. Prioritizing quality also improves the brand’s reputation, which can attract new customers and increase sales.

Conclusion

In conclusion, diecast quality services are an indispensable component of the manufacturing process, and are critical for ensuring that diecast products meet the highest standards of quality, reliability, and customer satisfaction. By investing in comprehensive quality control measures, manufacturers can prevent defects, reduce production costs, and enhance their brand’s reputation. The strategies, techniques, and best practices outlined in this guide are not just recommendations; they are essential steps toward achieving perfection in diecast manufacturing, and they play a crucial role in sustaining business success in today’s competitive market.